Beyond Storage: The Evolution of Industrial Plastic Bin Technology

In the dynamic realm of industrial settings, the role of Plastic Bins is pivotal in ensuring efficient organization, storage, and transportation of materials. These versatile containers come in various types, each designed to meet specific needs across different industries.Their advantages, ranging from durability and versatility to cost-effectiveness and sustainability, position them as indispensable tools across a spectrum of industries. The Industrial plastic bins have distinct features embedded in their design further enhance their utility, making them adaptable to the evolving needs of modern industrial operations. Their smooth, non-absorbent surfaces are easy to clean and sanitize, ensuring compliance with strict hygiene standards. This is essential in environments where contamination could have severe consequences for product quality and consumer safety.

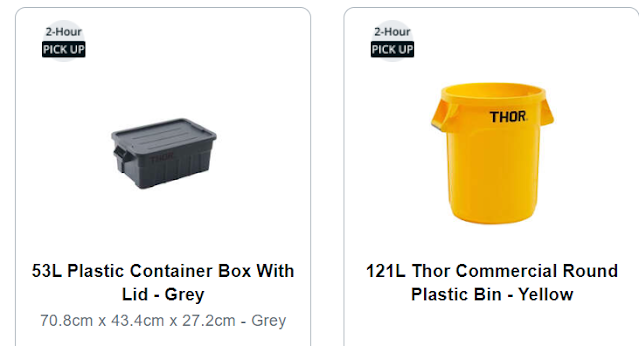

Industrial Plastic Bins: Their Types And Applications.

In this comprehensive exploration of Industrial plastic bins, we will delve deeper into the various types of bins commonly employed in industrial settings. From the straightforward stackable bins to the intricacies of conductive and FDA-approved containers, each type has a unique role to play.

Stackable Bins

Nesting Bins

Contrary to stackable bins, nesting bins are designed to save space when not in use. These bins can be nested inside each other, reducing the overall volume. This feature is particularly beneficial for industries with fluctuating storage needs, as it provides flexibility in space utilization.

Hanging Bins

Ideal for storage systems where accessibility is crucial, hanging bins come with integrated hooks or attachment points. These bins can be suspended on racks, panels, or other support structures, offering easy access to contents without the need for additional shelving. Industries with assembly lines or picking stations often find hanging bins indispensable for efficient workflow.

Attached Lid Containers

For secure and protected storage, attached-lid containers are a popular choice. These bins come with hinged lids that can be securely closed, protecting contents from dust, debris, and damage. The interlocking lids also facilitate easy stacking, making them suitable for industries where the preservation of sensitive materials is paramount.

Conductive Bins

In environments sensitive to electrostatic discharge (ESD), conductive plastic bins play a crucial role in preventing damage to electronic components. These bins are crafted from materials that dissipate static electricity, safeguarding delicate equipment from potential harm. Industries such as electronics manufacturing rely on conductive bins to maintain the integrity of their products.

FDA-Approved Bins

Industries involved in food processing, pharmaceuticals, or any applications where hygiene is paramount often turn to FDA-approved plastic bins. These bins are manufactured with materials that comply with the regulations set by the Food and Drug Administration, ensuring safety and suitability for handling food and pharmaceutical products.

Tilt Bins

Enhancing accessibility and visibility, tilt bins are designed with a sloped front that allows easy viewing and retrieval of contents. These bins are commonly used in settings where quick and organized access to small parts or components is essential, such as in workshops or manufacturing facilities.

Heavy-Duty Bins

Industries dealing with large, heavy items require bins with robust construction. Heavy-duty plastic bins are reinforced to withstand substantial weight and rough handling. Automotive and construction industries often rely on these bins to store and transport heavy parts and tools securely.

Conclusion

In the intricate tapestry of industrial operations, the variety of plastic bins available caters to a diverse range of needs. From optimizing space utilization to ensuring the safety of sensitive materials, these bins are indispensable tools for enhancing efficiency and organization in industrial settings. By understanding the distinct characteristics of each type, industries can make informed choices that align with their specific requirements, contributing to streamlined processes and improved overall productivity.

Comments

Post a Comment